Flint-Coat

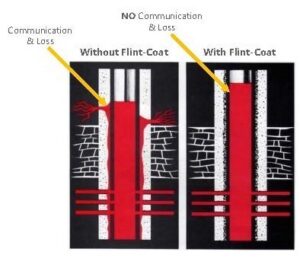

Flint-Coat is a high-temperature resin embedded with flint shards to create an extremely rough and hard surface for the OD of casing. It significantly enhances cement bond to casing as well as acting as a corrosion barrier. Flint-Coat is resistant to CO2, brine, and H2S, prevents gas migration, and provides cathodic protection.

Due to its hardiness, Flint-Coat can be used as production casing through unconsolidated zones, in corrosive environments, and as a coated tubing between injection intervals.

Features and Benefits

– Improves bond between cement and casing

– Chemically inert

– Resistant to CO2, brine, and H2S

– Resistant to abrasion and damage

– Significantly improves cement bond through unconsolidated formations

– High retention with wet cement

– Provides cathodic protection

– Highly temperature resistant

– Can be deployed selectively in casing string